Technique

Technical complex

Film Microheaters

Semiconductor gas sensors

Thermocatalytic gas sensors

Thermoanemometers

Gas test equipment

Thermoanemometers.

|

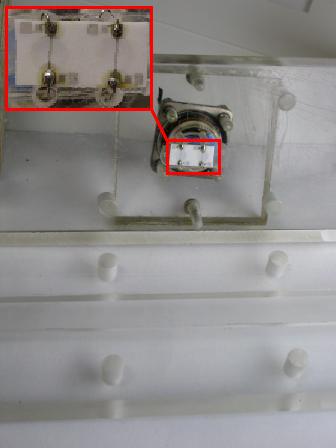

Modern flowmeters have thermoanemometer tester of air flow. It works as: heat exchanger element from a thin platinum wire (diameter about 0.07 mm) disposed in the flow of air The increase of air flow leads to an increase in the electric power for maintaining of the desired temperature difference between the wire and wrapping it air. The amount of heat, carried away by the gas flow, depends on the physical characteristics of a moving fluid, on the geometry and orientation of the wire. It is known, that increasing of the wire temperature and growing of the area of contact between the gas and the heating elements, increases the sensitivity of thermoanemometers. The most modern meters are the film thermoanemometers. They have heating and measuring resistors produced as a thin platinum layers, deposited on the surface of a silicon crystal. Using thin-film chips, created by the TAF-technology, can further improve their sensitivity. An important feature of offered products is not required to reduce the cross-section of gas pipeline, when low rates flows are measured. |

|

Here are the results, obtained in the calibration thermoanemometer tester of air velocity.

|

|